Important Guide to Strapping Machine Repair: Making Certain Optimal Performance and Longevity

Strapping machines play an important function in packaging and logistics. They can come across various issues that hinder their performance. Understanding these usual issues and their hidden causes is essential for reliable repair service and maintenance. Proper diagnostics and normal upkeep can expand a maker's lifespan significantly. Yet, many drivers overlook important maintenance steps. What are one of the most effective strategies for making sure these machines run at peak effectiveness? The solutions may shock you.

Common Strapping Machine Issues and Their Causes

Although strapping machines are essential for reliable packaging procedures, they can run into different problems that disrupt operations. Usual troubles include misfeeds, where the strap does not feed properly with the device, often brought on by incorrect placement or used components. Another frequent issue is strap damage, which can arise from using the wrong type of strap or extreme stress throughout the strapping procedure. Additionally, inconsistent seal stamina may take place because of insufficient warm or pressure settings, resulting in damaged or weak seals. Dirt and particles build-up can likewise trigger mechanical failures, hindering the machine's efficiency. Operators might additionally experience electrical malfunctions, such as defective sensors or control failures, which can halt production. Recognizing these issues and their underlying reasons is important for maintaining optimal performance and making sure the durability of strapping machines in packaging operations.

Essential Devices for Strapping Machine Repair

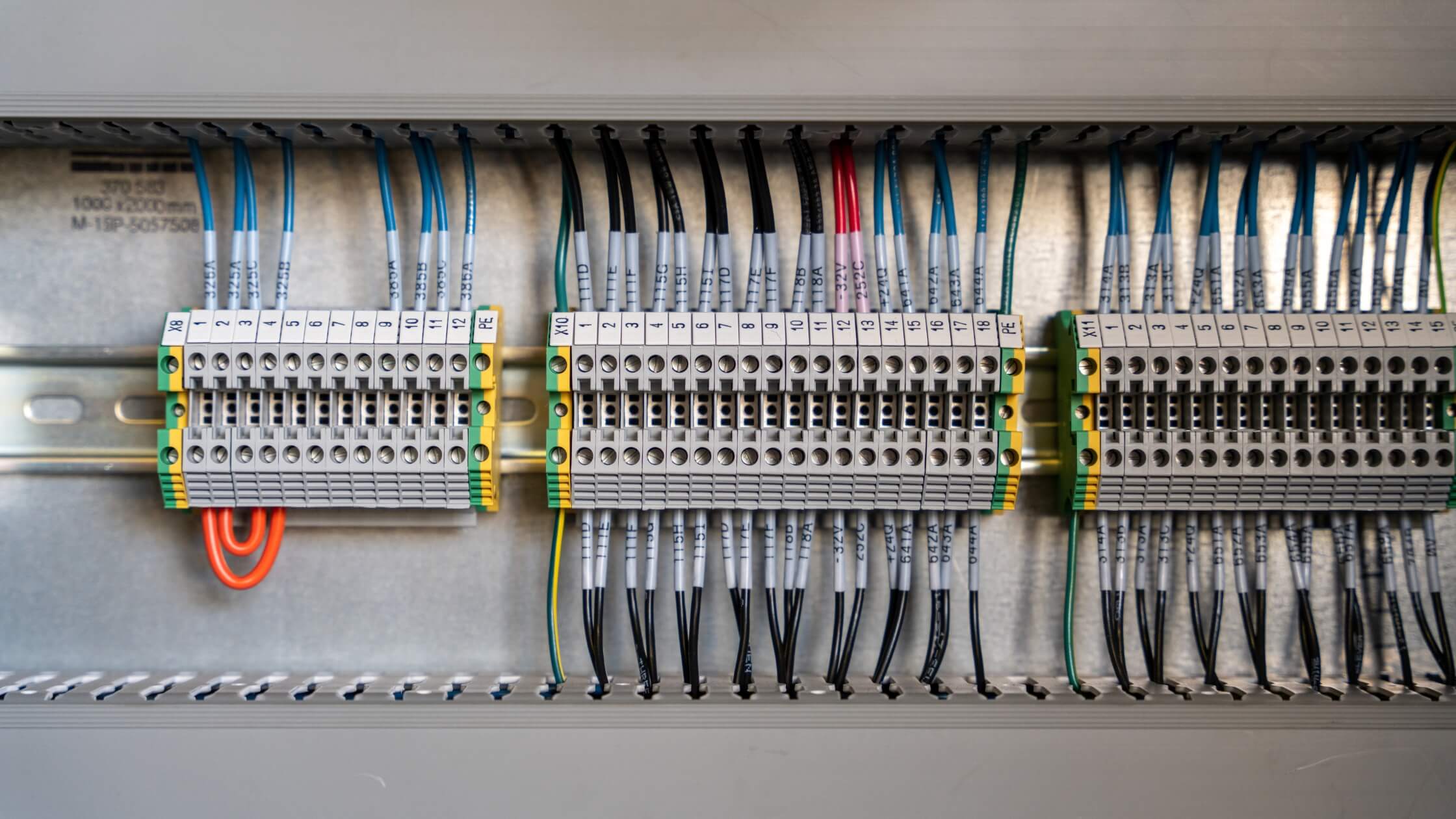

Attending to the typical issues that strapping machines come across needs the right tools to assure efficient repair work and maintenance. Important devices include wrenches, pliers, and screwdrivers, which are crucial for taking apart and reassembling elements. A multimeter is essential for diagnosing electrical problems, allowing technicians to determine damaged connections or components. Furthermore, a torque wrench warranties that screws are tightened to the supplier's requirements, preventing future malfunctions. Lubricating substances and cleaning up supplies are essential for routine upkeep, ensuring smooth procedure and long life of the device. Substitute components, such as sensing units, motors, and belts, must also get on hand to help with fast repair services. A thorough fixing manual provides indispensable support, aiding professionals browse the complexities of strapping maker fixing efficiently. Utilizing these devices properly can substantially enhance the efficiency and life-span of strapping machines, minimizing downtime and operational disruptions.

Step-by-Step Troubleshooting Overview

Just how can specialists effectively identify and solve concerns with strapping machines? An organized strategy is essential. They must determine the signs, such as inconsistent strapping or machine jams. Next off, service technicians must review the customer guidebook for specific mistake codes or troubleshooting steps connected to the observed issues.

When signs are kept in mind, they need to check the device's parts, consisting of the tensioner, sealing head, and feed system for wear or damages. It is necessary to look for proper alignment and any kind of obstructions. After aesthetic examinations, service technicians ought to test the electric connections and sensing units to guarantee they are operating properly.

If problems linger, carrying out a useful test after each change will assist isolate the concern. Recording each step taken is very important for future referral. Following this organized troubleshooting overview allows service technicians to successfully pinpoint the trouble and execute efficient repair services, thus read here enhancing equipment dependability and efficiency.

Preventative Maintenance Tips for Durability

Applying a robust preventative maintenance plan is crucial for guaranteeing the longevity of strapping machines. Normal assessments need to be carried out to recognize any indicators of wear or damages, concentrating on crucial components such as belts, sensing units, and rollers. strapping machine repair. Cleaning up the maker regularly aids protect against debris buildup, which can result in operational issues. Lubrication of moving parts is necessary; using the maker's recommended lubes assurances smooth operation and minimizes friction

Furthermore, drivers should check the equipment's efficiency metrics, keeping in mind any type of abnormalities that may show prospective issues. Keeping a comprehensive maintenance log help in tracking solution history and scheduling prompt treatments. Training staff on proper use and handling can noticeably minimize the threat of operator-induced damages. Replacing used elements proactively, instead than reactively, can lessen downtime and prolong the maker's life expectancy. Adhering to these preventative maintenance tips will add to suitable performance and durability of strapping machines.

When to Look For Professional Help

Furthermore, when parts reveal indications of wear or damage, professional evaluation comes to be crucial to assure safety and performance. If in-house maintenance personnel lack the proficiency or i thought about this tools to identify complicated issues, looking for assistance from skilled service technicians is a good idea. Normal assessments with specialists can likewise aid in identifying potential issues prior to they rise. Ultimately, prompt intervention by professionals not only extends the lifespan of the devices however additionally safeguards performance, ensuring that operations remain smooth and effective.

Often Asked Questions

How Often Should I Change the Strapping Machine's Components?

Strapping machine components ought to be changed every 1-3 years, depending upon usage and wear (strapping machine repair). Normal assessments and maintenance can help recognize parts requiring replacement sooner, making linked here certain excellent performance and decreasing the risk of unanticipated malfunctions

Can I Utilize Different Strapping Products With My Machine?

Various strapping materials can often be made use of with a machine, supplied they fulfill certain size and stress demands. Nonetheless, compatibility ought to be verified to ensure peak performance and protect against prospective damages or malfunction.

What Are the Indicators of a Getting Too Hot Strapping Machine?

Signs of an overheating strapping machine consist of uncommon noises, frequent closures, excessive warmth emanating from parts, smoke, and inconsistent strapping high quality. Prompt identification of these signs is necessary for avoiding damage and making certain reliable procedure.

Exactly How Can I Boost Strapping Speed Without Compromising High Quality?

To improve strapping rate without giving up high quality, one can maximize equipment setups, make use of high-quality materials, maintain equipment routinely, and train operators in effective strategies, ensuring a balance in between rate and efficient strapping performance.

Are There Particular Brands Known for Better Durability?

Particular brand names, such as Signode and Mosca, are renowned for their toughness in strapping machines. Their durable building and premium products often bring about prolonged life expectancies and reputable performance in requiring commercial atmospheres.

How can technicians successfully identify and resolve concerns with strapping machines? They ought to determine the symptoms, such as irregular strapping or maker jams. Applying a durable preventative maintenance strategy is important for guaranteeing the long life of strapping machines. Different strapping materials can usually be utilized with a machine, given they satisfy details size and stress demands. Signs of a getting too hot strapping machine consist of unusual sounds, frequent closures, excessive warm originating from components, smoke, and inconsistent strapping top quality.